Choose a Source Soft Starter Manufacturer for Better Value & Quality

Why Soft Starter Manufact

Learn how to safely integrate soft starters into circuit systems, ensuring proper wiring, protection, and compliance with electrical standards for reliable motor control.

Soft starters are critical for protecting motor systems from electrical stress, but their effectiveness depends on proper circuit integration. Safely connecting a soft starter involves more than just physical installation—it requires matching electrical parameters, implementing protective measures, and adhering to industry standards. This guide outlines the key steps to ensure your soft starter operates safely and efficiently within any circuit system, minimizing risks of overloads, voltage fluctuations, and equipment damage.

Before wiring a soft starter, verify these critical compatibility factors:

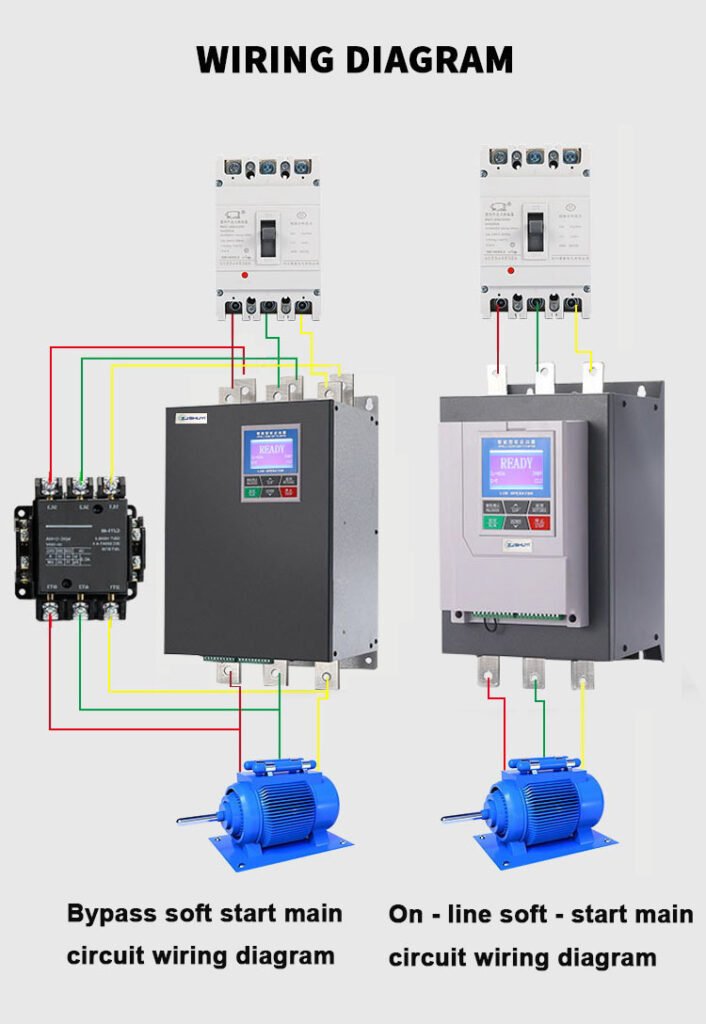

Proper wiring is essential for safe operation:

Integrate these components to safeguard the circuit:

Adhere to these global standards for safe integration:

Address these frequent challenges during installation:

Safe circuit integration of soft starters is a critical step in optimizing motor performance while ensuring operator safety and equipment longevity. By prioritizing compatibility checks, following proper wiring procedures, and implementing robust protection measures, you can minimize risks and maximize the benefits of soft starter technology. Always refer to the manufacturer’s guidelines and local electrical codes to ensure compliance, and conduct regular maintenance to keep your circuit system operating at peak efficiency.

Contact Us

Tel/Fax: 0086-577-62840011

Wechat/WhatsApp: 00861586807525

Why Soft Starter Manufact

Industrial Limit Switches

Enter your request below and send it to us, and we’ll get back to you ASAP!

Enter your request below and send it to us, and we’ll get back to you ASAP!